Galore Creek Mine, British Columbia

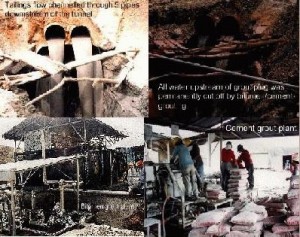

A pilot grouting program to assess the feasibility of the construction of a tailings dam.

A pilot grouting program to assess the feasibility of the construction of a tailings dam.

A multiple pass, multiple hole permeation grouting operation directed by ECO was implemented via driven, vertical steel sleeve pipes to encapsulate and contain nuclear waste buried in trenches and prevent the migration of radionuclides.

Quick turnaround for grout curtain through rock not amenable to regular or microfine based cement grout.

Grouting techniques can also be used to prevent wind erosion and keep moisture in the soil. A four acre miniature forest was grown in the Sahara desert (Southern Tunisia) using a specially developed solution grout. It was sprayed on the sand after small Acacia Cyanaphylla trees were planted.

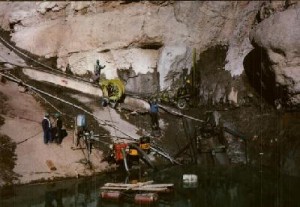

Hot bitumen injection, in conjunction with regular cement based suspension grouts, was employed to stop a major tailings flow, which peaked at approximately 7,000 l/sec (111,000 US GPM).

A double row grout curtain was constructed around the perimeter of 2 large diameter (100 plus ft) caisson shafts using acrylamide and cement based suspension grout to stabilize and control the water inflow prior to sinking the shaft through the soil and rock formations.