Milleville, USA

1997 - 1998

During a routine mining operation of the old limestone quarry a karstic geological feature was encountered some 200’ below the Shenandoah River. The hydrologically dormant feature was connected to the river and caused inflows into the quarry of over 50,000 gpm.

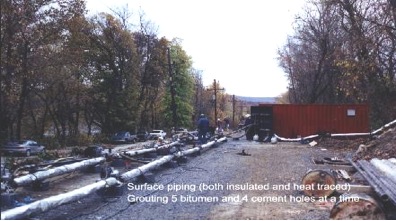

It was determined that karsts, as high as 70 feet, were acting as river-water seepage conduits. ECO recommended the technique of hot bitumen grouting in conjunction with cement grouting to successfully treat the inflow.

Special techniques that were designed and supervised by ECO were:

- Hydro-thermal mapping to differentiate between river-inflow and static groundwater

- Hot bitumen grouting in conjunction with cement grouting.

- Compaction grouting to stabilize the overburden and low flow karsts.

- Downstream well pH monitoring to determine the amount of cement washout during grouting operations.

- Permeation grouting with custom tailored water repellant cement based grouts in areas with low flow.

- Custom designed dual zone bitumen stingers were used to provide simultaneous injection of bitumen and cement based suspension grouts to targeted zones

A grout curtain 1,050 feet long by 200 feet deep was successfully installed and the quarry inflow from the river was successfully reduced back to production levels. Upon completion of the project in December 1998, the inflow had been stopped.