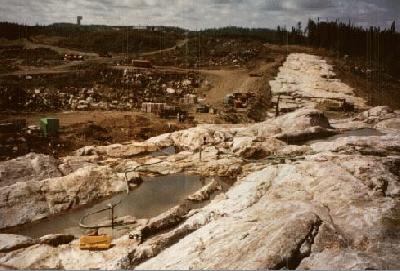

Manitouwadge, Ontario

April to September 1991

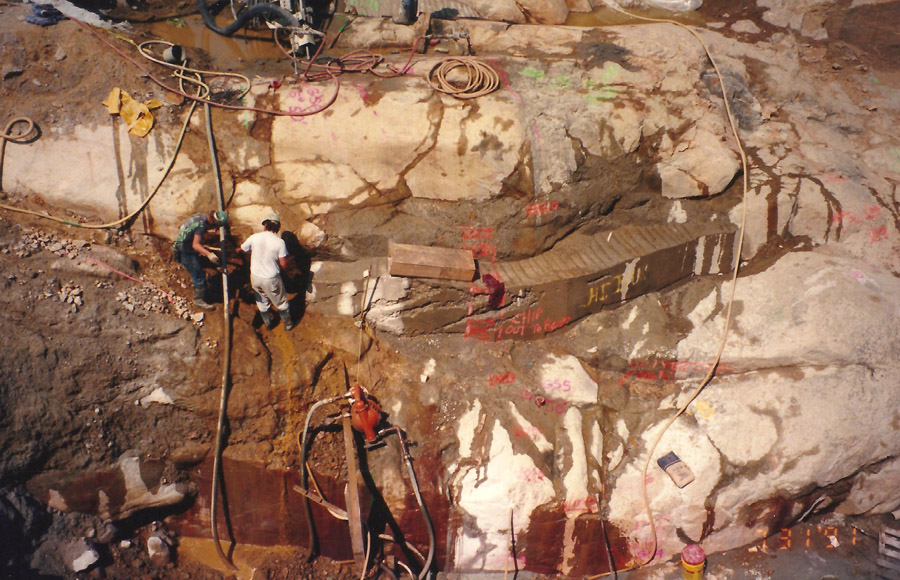

A grout curtain 1,050 metre long and 13.5 metre deep was installed for the construction of new tailings dam at the GECO Mine. It was constructed using regular Portland cement and microfine cement based suspension grouts.

ECO, as a sub-consultant to DNE (now Knight Piesold), designed and directed the grouting operation. The bedrock conditions ranged from highly weathered fault and shear zones to competent bedrock with semi-horizontal stress relief cracks.

By constantly monitoring grouting parameters and applying our Amenability Theory, ECO was able to instantaneously adapt grout formulations to suit the conditions encountered. This analysis also served to further define the model of subsurface conditions throughout the operation. The importance of such grouting engineering was exemplified at GECO; another project conducted concurrently with this one, under similar initial conditions, resulted in a residual permeability of 5 Lugeon at three times the cost.

This grout curtain had a final residual permeability of less than 1 Lugeon.