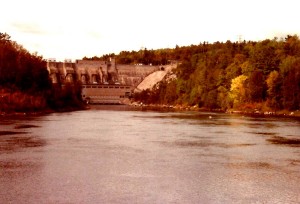

Ontario, Canada

1984

Two high velocity water flows (22,500 l/minute on the South side & 21,500 l/minute on the North side) through fissures in the limestone formation beneath a concrete hydro dam structure were successfully stopped. For several years, grouting programs had been executed using regular cement based suspension grouts with a myriad of additives. These grouting attempts did not result in a reduction in seepage. A substantial flow discharged into the inspection tunnel of the dam created unsafe working conditions. There was also concern that the water flow would continue to increase due to erosion of more gouge from fissures through the limestone formation below the dam.

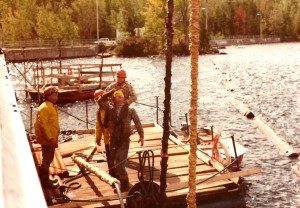

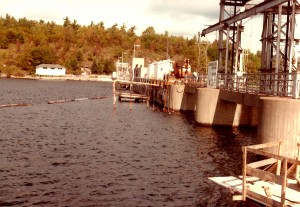

The flows were successfully sealed by simultaneous injection of hot bitumen and cement based suspension grout. The hot bitumen was necessary to deal with the high velocity water flow. The cement grout was placed behind the bitumen plug to impart strength and permanence to the plug.

During the 1983 operation, the leak on the south side was sealed. Within 4 minutes of grouting, this stubborn leak was stopped, however the operation continued for several more hours to ensure the formation was adequately plugged reducing the residual permeability to 0 Lugeon. During the 1984 operation, a leak of the same magnitude on the north side was grouted the same way. This time, the grouting operation only lasted a couple of hours.

In order to attain this success, it was necessary for ECO to develop advanced grouting techniques and for Ontario Hydro to be willing to accept this “new” concept of injection of hot bitumen in conjunction with cement based suspension grout.

The Stewartville Dam grouting project was the first hot bitumen operation to stop major inflows in Canada. The hot bitumen grouting technology was re-introduced and developed by ECO.